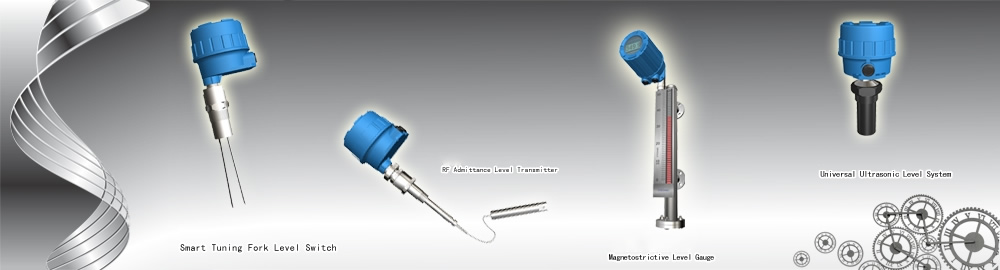

FT8511 series Magnetostrictive Coupling Level Gauge

FT8511 serial coupling magnetrostrictive level gauge is based on magnetostrictive principle. It is comprised of one magnetrostrictive level system and one magnetism vane liquidometer, two wire intrinsic safe design, mainly for accurate process level control and storage tank volume measurement/control in petroleum、power、chemical、metallurgy、light industries etc.

This product is a bundle constitution of one magnetism vane liquidometer and one magnetostrictive level system.

》》》》Operation Principle

Sensor is the center of the magnetostrictive monitoring system, and the core sensitive component(magnetostrictive wire) of the sensor need has high adapted ability、strong convert capability of electrical(magnetic) /mechanical wave to transfer the small magnetic vector change to be a mechanical wave. Sensor is comprised of stainless steel rod(inside include supper magnetostrictive wire) and float(inside include rare earth permanent magnet) two parts. While the pulser of electronic part emits a electric pulse transmit along with the magnetostrive wire inside of the steel pipe, the electrical pulse also accompany generate an annular magnetic field vertically to the wire,and the field transmit along with the wire at velocity of light.When the annular filed of the electrical pulse meets the fix filed of the float, the two magnetic fields interacts each other, then occurs instant torsional force and form a mechanical torsional pulse wave on the wire. This mechanical torsional wave use a fixed speed return to electronic part and be picked up by that part. According to the time difference between the emitted electric pulse and the returned torsional wave, the material level or interface could be accurate calculated out.

》》》》Characters

Ø High temperature high pressure:-196~450℃(-321~842℉), 10Mpa(1450psi)

Ø Two display outputs:Except Magnetism vane liquidometer provide local indication, the magnetostrictive level system also support 4-20mA output to go to the main control room

Ø Easy installations:Outside vessel installation gives convenience for field mounting、calibration and

maintenance while no affection to the process production line

Ø High accuracy:instrument accuracy reach 1mm

Ø Modular design:The sensing element and electronic unit could be interchange between different

system, easy for spare and maintenance.

Ø Remote installation:Suitable for multiple dangerous/harsh applications, convenience for control and

monitoring

Ø HART communication : Built-in two wire field 4-20mA HART protocol

Ø Field keyboard calibration:The two keyboards on the top the electronic could calibrate the

Ø high/lower level points easily in the field

Ø Refined oil storage tank

Ø Liquefied gas storage tank

Ø Variable chemical reagents

Ø Process tank leakage detection

Ø Water & wastewater treatment

Ø Other high accuracy level detection

》》》》Specifications

Ø Measuring rate of facility: CAT I, transient over voltage 1500V, only use the equipment for

measurements within measurement category I

Ø Output:4~20mA,HART digital protocol, output direction software adjustable

Ø Measuring Type:Level(DIR) or Distance(REV) field adjustable

Ø Power requirement:12~35VDC; For communication: 15~35VDC

Ø Dissipation power: less than 0.5W

Ø Accuracy: ≤0.1%FS or 1mm (which greater)

Ø Resolution: ≤0.04%FS or 0.4mm (which greater)

Ø Repeatability: ≤0.04%FS or 0.4mm (which greater)

Ø Linearity correction: 10 points non-linearity correction by software (if necessary)

Ø Temperature Affection: 0.05%/10℃(18℉)

Ø Load resistance:24VDC output loop resistance 600Ω

Ø Ambient Temp.:T5:-40~+70℃(-40~158℉);T6:-40~+60℃(-40~140℉)

(Effect of the process temperature on the environment temperature should not exceed the

environment temperature requirements of the instrument.)

Ø Response Time: < 2 seconds

Ø Time Delay: 1~90seconds adjustable(software)

Ø Range:0~5m(rigid) ,0~20m(flexible cable)

Ø Dead Zone:Upper zone: ≤ 1/2 float height

Lower zone: Rigid sensor- 1 float height;Cable sensor- 250mm to 450mm

Ø Max. process temperature: -196~+450℃(-321~778℉,for details please see probe specifications)

Ø Max. process pressure: 10 MPa(1450psi) (for details please see probe specifications)

Ø Process density: 0.38g/cm3~2g/cm3

Ø Cable length: max . remote cable 3m

Ø Electrical connection:double M20×1.5 (3/4” NPT optional )

Ø Process connection:Double flanges(measuring displacer installation)

Ø Housing Material: Die casting aluminum epoxy coating

Ø Explosion-proof rating:Exia IIB T5/T6 Ga & Exd IIBT5/T6 Gb

Ø Ingress protection:IP67

Ø Approval:PCEC/NEPSI, for other approval please consult factory

》》》》Magnetostrictive Coupling Level Gauge Installation Requirements

l Installation、Utility & Maintenance of the instrument should comply with the instruction manual and

GB50257《Construction & Verification Standard of Electrical apparatus mounting in explosion or flaming dangerous area》、GB3836.15 & GB3836.13 requirements.

l The mounting location of the instrument should free of vibration, high temperature, corrosive atmospheres, or any possibility of mechanical damage for maximum service life. If this is not possible, consider a remote system installation. Ambient temperature should be between -40 ~70oC (-40 ~158oF ).

l Instruments installed outdoors in areas of lightning strikes should be installed with lightning protection.

l DO NOT ADOPT MONO-COMPOSITION ENCAPSULAION SEALING inside of instrument housing since most of that kind of encapsulation will contain acetic acid. (Acetic acid could decay the electrical component.) Please consider to use SPECIAL DOUBLE-COMPOSITION ENCAPSULATION (non-erosive).

l The instrument has ground terminal on its housing. Please connect the terminals to the field ground properly during installation. For non-metallic vessel/tank installation, the filed should provide a standard ground. CONNECT TO DYNAMIC GROUND IS FORBIDDEN!

l Cable inlet should meet GB4208 standard requirements reach IP65 code to ensure reliable electrical connections. It will avoid water or other corrosive gas destroys the electronic unit.

l Do not open sensing element or loosen sealed gland. That may cause system leakage.

l Only the mounting screw or flange part of the sensing element need be well connected to the vessel, reliable sealed and electrical connected properly. Any other parts of the sensing element should not touch the vessel to ensure float works well.

l Keep any ferromagnetic material at least 200mm away from the sensing element.

l For explosion-proof instrument installation, cable inlet should come with approved cable accessory such as XP fittings or XP steel conduit sealings according to GB3836.1 & GB3836.2 explosion-proof standard requirements.

l For intrinsic-safe instrument installation, the loop should come with approved barrier according to GB3836.1 & GB3836.2 explosion-proof standard requirements.

l 24VDC Instrument power noise should be lower than 100mV.

l Power wire should meet IEC60245/60227 standard requirements Recommended as 3 terminal armature cable, cable O.D. should less than 12mm, conductor material of the cable is copper, section area should between 0.13 –2.1 mm2(AWG14-26), insulating capability 1500V. And associated switch should meet IEC60947 requirements. Do not make the unshielded cable parallel with power supply cable for long distance..

l Strict follow “STOP OEPN THE LED WHILE POWER ON” during field operation or maintain, recommended operate 10 minutes after power off.

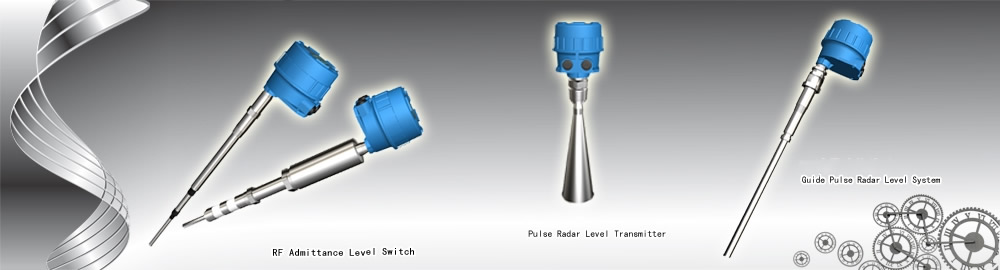

Products

Products